| Home > Material > Natural Materials > Silicone |

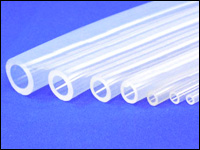

Silicone |

Known as the combination of inorganic and organic polymers, Silicone comprises silicon, hydrogen, carbon, oxygen and few other chemical elements, in special formulations. The chemical formula for silicone is [R2SiO]n, where R is an organic group like ethyl, methyl, or phenyl. Few of the general form this natural material that are available commercially are silicone rubber, silicone oil, silicone resin and silicone grease.

Synthesis:

Silicone are generally synthesized from:

- Chlorosilanes

- Tetraethoxysilane

However, in modern times, silicone resins are processed from tetraethoxysilane rather then chlorosilanes as it reacts in a relatively mild and manageable manner.

Few important properties of silicones:

- Silicon is a bad conductor of electricity. Further it can be developed to be electrically insulative or conductive, and hence enjoys end number of applications in the electrical industry.

- Displays excellent thermal stability

- Though not a hydrophobe, it has the ability to repel water and are used in making water tight seals.

- It is oxygen, ozone and UV light resistant. Therefore it is used as coatings, fire protection, and glazing seals in construction work and in making external gaskets or external trims in the automotive industry.

- Does not stick.

- Low chemical reactivity.

- Low toxicity, but does not support microbiological growth.

- High gas permeability at room temperature (25 °C). Silicone rubbers can never be employed where gas-tight seals are required.

- Silicones are are not fully soluble in water and so enjoys extensive usage as as an active compound in defoamers .

Mechanical properties of Silicones: Mechanical properties of Silicones:

- Hardness, shore A : 10–90

- Tensile strength : 11 N/mm²

- Elongation at break : 100–1100%

- Maximum temperature : +300°C

- Minimum temperature : -120°C

|