| Home > Machinery > Confectionery Machinery |

Confectionery Machinery |

Confectionery industry is an important field of modern times with the rapidly increasing demand of sugar based desserts worldwide. The word 'confectioner' is originated in the Latin word confection. Colorful candies are a popular medium of expressing joy during any festive season. Its difficult to realize that behind these sweet and delicious candies, lots of efforts and high-end machinery are there, in fact it is one of the biggest industries in the world. A recent study reveals that in India adult consumption of chocolate & candies is increasing in a rapid manner. Almost 20% of chocolate sales in retail shops comes from adult consumption.

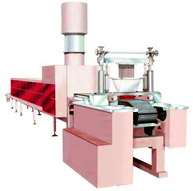

The dessert making is a tough process as it requires various kind of formulation like mixing, kneading, flavoring, baking and cooling. Like other fields technology has also revolutionize the confectionery industry. For each of above mentioned processes, separate machines & mechanism are required. Some of the commercially available Confectionery Machinery for this industry are Flavor Mixer, Hi-Speed Toffee Machine, Cooling Drum, and Batch Kneader.

Flavour Mixer:

Flavour Mixer:

Flavour Mixer is one of the simple confectionery machinery, which is used to mix a large number of flavors, colors & acids into boiled sugar. This heavy duty machine carry out the mixing with two coated plates. These are operated on a simple sloping axis. After this, sugar is moved from the cooker and with the support of a trolley the mixture is properly mixed in the bowl.

Cooling Drum:

Cooling drums are high-end and automatic equipment, which comprises cooling drums made of stainless steel. After the enrobing process, these drums are used to transfer the entire mixure into a favorable temperature.

Hi-Speed Toffee Machine:

These modern machines are used to make toffees. Following are the features of this machines:

- The sealing units have automatic temperature control

- Extra cooling of fold wrap

- The operation of the machine is stopped automatically for wrapping material troubles

- Easy operation and low maintenance

|

| |

| |

|