| Home > Material > Commonly used Materials > Polycarbonate |

Polycarbonate |

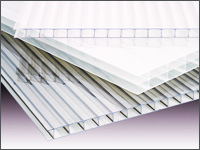

One of the commonly used materials in the rotomoulding machinery, Polycarbonates are commercially marketed under the trade names Makrolon and Lexan. It is a group of high-performance and lightweight thermoplastic polymers. The engineering grade Polycarbonate are very stiff and has the features of very high heat resistance, creep resistance and tensile strength. Also, they are quite resistant to scratch and display appropriately high melt flow index (MFI). Therefore, when processed immaculately, these thermoplastics can be very easily worked on, molded or even thermoformed, making them an excellent choice for engineering applications like casting, injection molding and rotomolding.

Structure and Production of Polycarbonate:

Structure and Production of Polycarbonate:

Most polycarbonates have two Alkyl on the end with carbon-carbon double bonds in them. As a result, when they polymerize by free radical vinyl polymerization all the carbonate containing groups cross link between the polymer chains. This makes them very strong and impressively resistant to heat.

Polycarbonate are prepared by reacting bisphenol A or dihydroxybenzophenone with sodium hydroxide, which deprotonates the hydroxyl groups yielding diphenoxide and water. The diphenoxide is reacted with phosgene (COCl2) to give a chloroformate which is then treated by another phenoxide to obtain the polycarbonate material.

|

| |

| |

|